One could say that a fan is probably the most omnipresent appliance in India. As an appliance that is a norm in almost every household across India (and increasingly across the globe), the fans industry is currently underrated. In terms of value, the sector is valued at around Rs. 8,000 crore (US$ 1.07 billion), and it produces 60 million units annually. The industry is witnessing an increasing demand year-on-year and undoubtedly is poised for growth. Add to that the fact that we live in an era that has seen more change than ever before with evolution in technology and consumer tastes and preferences. The pandemic too, brought about major shifts in consumer behaviour, further pushing the industry to revolutionise.

If you see the glass half full, you’ll agree that as an industry we have been provided with the much-needed impetus to innovate; and innovations in our sector range from tech to aesthetics, all crafted to suit the lives of our consumers. Technological changes are rapid and are continuously leading to newer solutions that offer better air delivery rate and longer life. An important change comes in form of demand for energy saving appliances. Aesthetics is another key area of prime interest to the consumers and has seen a swift demand over the last couple of years. Staying in at home and rise of social media has created a large demand for an attractive home and thereby demanding appliances look great. We have seen an increase in demand for stylish designs & innovative technologies by households and large players are already capitalising on the demand by offering fashionable yet quality-oriented products. This trend has hit the refresh button for the industry which will only further strengthen the market.

To summarise, we’re at a cusp of major change and the manufacturers should have the following in mind to serve consumers better –

1. Continuous innovation will provide an upper hand. Technology is becoming a major factor in economy as a whole and those will adapt to the innovation culture will excel.

2. Energy efficiency is crucial to consumers. BEE rating is going to be mandatory, and every manufacturer will comply but those who will further march ahead will lead.

3. Aspirations of the country is growing. This means that products must fulfil the expectations in terms of aesthetics and a premium touch.

The Indian Fan Manufacturers Association has played a catalytic role in re-instating these ideologies since its inception. It has been committed to aligning parameters imperative to the survival and growth of the fans industry. With the continuous efforts that the manufacturers and the association have put in to develop quality, sustainable and energy-efficient products, the fans industry has the right mantra to woo consumers and thus witness growth in the years to come.

Frequent storms, torrential rains, flash floods, severe droughts, fierce wildfires, and the list goes on. Climate change has started to impact human lives more evidently and severely. This has drastically changed consumers’ sentiments and their ways of purchasing and interacting with the products. They are becoming more conscious of their purchases and consumption. One such stark transformation we can experience today is in the space of transportation, consumers are adopting more eco-friendly electric vehicles instead of fossil fuel guzzlers.

This shift will be experienced in the Electrical consumer durables space too and ceiling fans are one of those. But even though ceiling fans are arguably the most ubiquitous electrical device in Indian homes and businesses after electric lights, they are rarely discussed in conversations about energy saving. As a result of this oversight, a considerable possibility for energy savings has been lost. Fans utilize nearly 20% of the electricity in Indian households, and their use is steadily increasing. In India, total organised fan production is around 60 million units per year. After deducting 30% for table and pedestal fan sales and exports, annual ceiling fan sales in India are estimated to be around 45 million.

Thus Ceiling fans have a lot of potential for reducing power consumption. Thanks to a technology known as Brushless DC Motor, or simply BLDC motor. This technology is on the verge of causing a paradigm shift in the ceiling fan business. In general, BLDC technology has been on the market for a few decades and is widely used in industries that require high torque motors. What has been missing for a long time is its use in ceiling fans. Induction motors are used in classic fans, and they normally consume 70-90 watts. The power consumption of a BLDC fan, on the other hand, can be reduced by up to 65 percent. Other advantages of using BLDC fans are longer backup on inverters even on Solar, increased reliability, decreased noise production, and longevity of the motor.

The market share of BLDC fans is expected to grow exponentially in the coming years. With the declining cost of electronics cost of manufacturing, BLDC fans cost will reduce significantly. BLDC motors are becoming more popular also due to industry demands for lighter weight, smaller size, and higher power density. The cost of BLDC fans is more, but when we consider the rising cost of power, choosing a super-efficient 5-star rated BLDC fan makes a lot of sense. With the BEE making the requirements for achieving a 5-star energy certification more stringent, the newest rated models are exceptionally energy-efficient, utilizing only 25-35 watts of power.

Looking at the shifting consumer centricities, government policies, and building a sustainable environment adoption of BLDC fans is set to grow. Consumers are also more aware and are shifting towards more eco-friendly ways of living. Due to shifts in ways of working, WFH, and hybrid cultures the interaction with fans as a commodity at home has changed. Consumers want fans that are more premium and provide them savings. As said by Wendell Philips “Revolutions never go backward”, this revolution of BLDC fans is set to change the fans industry radically and bring a wave of highly efficient eco-friendly fans.

As the saying goes, the Stone Age did not end because we ran out of stones; we transitioned to better solutions. The same opportunity lies before us with energy efficiency and clean energy. – Steven Chu

Energy Efficiency simply means using less energy to perform the same task – that is, eliminating energy waste. Energy efficiency brings a variety of benefits like -lowering household costs and the whole economy, reducing demand for energy imports and reducing greenhouse gas emissions.

India’s leadership for energy efficiency has been greatly strengthened through the years. With the Prime Minister setting an aim to make India energy-efficient by 2047, various initiatives are being taken by the government to advance the regulations that reduces and transforms energy consumption.

IFMA, the Indian fan manufacturers association is also committed towards the vision of energy conservation and has whole heartedly welcomed and embraced the mandatory BEE (Bureau of Energy Efficiency) star rating program for ceiling fans from July next year.

IFMA has embarked on the same without compromising on the basic parameters like Air Delivery and other parameters which are of paramount importance to a consumer. IFMA members and other fan manufactures are confident about the success of this BEE initiative thereby ensuring that Indian consumers would be catered and served by genuine and serious manufacturers whose vision are in sync with the Global vision.

It has also been observed that over the years, the consumer purchasing behaviour has changed. They are now not just looking for basic fans but models that are aesthetically in sync with their home decor, high in performance / durability and energy efficient. Because of this behavioural change BLDC motors in Fans being energy efficient are also becoming extremely popular. Due to urbanisation and increasing ‘purchasing power’, it is estimated that the number of individual households and the number of appliances in every household will keep increasing. This phenomenon would make it imperative for all appliances especially fans to be power efficient and would be in complete ‘synergy’ with the BEE and IFMA combined initiative.

IFMA commits to be the frontrunner in embracing sustainable and energy-efficient technology and ensuring effective implementation of all Government initiatives especially the BEE Star labelling requirements.

Relying on the new age, aesthetics, and innovation & technology and now energy saving, it can be summarized and concluded that the fan industry is indeed entering in a “golden era”.

The invention of the electric ceiling fan is one of the major milestones in the history of mankind, and it all began in the late 19th century when the first electric fan was invented in the USA. Later, during the early 20th century, companies such as GE Westinghouse, Emerson, and a few more started producing electric fans on a mass scale, and by the 1920s electric ceiling fans became commonplace in the US.

But that’s about America getting their first electric fans. What about India?

When did fan manufacturing begin in India?

And when did India get its first electric ceiling fan?

Well, the history of electric fan manufacturing in India is not well documented, so it will be difficult to put an exact date and chronology to that. But let’s say that it all began in the 1930s and by the 1940s quite a few established manufacturers started manufacturing electric fans in Calcutta.

Come, let’s take you on a journey that gives us a glimpse of some of these pioneers of Indian fan manufacturing who led this revolutionary change from the mid-19th century to the late 1950s.

The Pioneers of that era

Several prominent names such as Clyde, IEW (India Electric Works), Orient, Usha, Kassels, Crompton Parkinson forayed their way into manufacturing electric fans in India. The range of Fans included Ceiling fans, table fans, and Railway carriage fans apart from Air Circulators for Industries

While most fan manufacturing companies started production during the 1930s and post that, here is an interesting fact shared by a writer in one of his blogs. According to him, Kshirode Bihari Chakraborty, a Bengali entrepreneur, set up Clyde Engineering Company Ltd, an electric fan manufacturing company, in the year 1918. By that account, he becomes the father of the Fan Industry in India unless contested. The writer also mentions that Kshirode Bihari Chakraborty was encouraged and financially supported by various native aristocrats that included the likes of Kumar Arun Singha of Paikpara and Maharaja Rajendra Kishore of Mymensingh, to set up this company in Calcutta. This is not yet contested but Yes, Clyde Fans were surely one of the early entrants.

IEW (Indian Electric Works) was another major player involved in manufacturing electric fans in India during the early 1930s. They gave India some robust electric fans that came with sturdy motors. In fact, you would be surprised to know that some of these fans are still in use at the Southern Indian Railway stations.

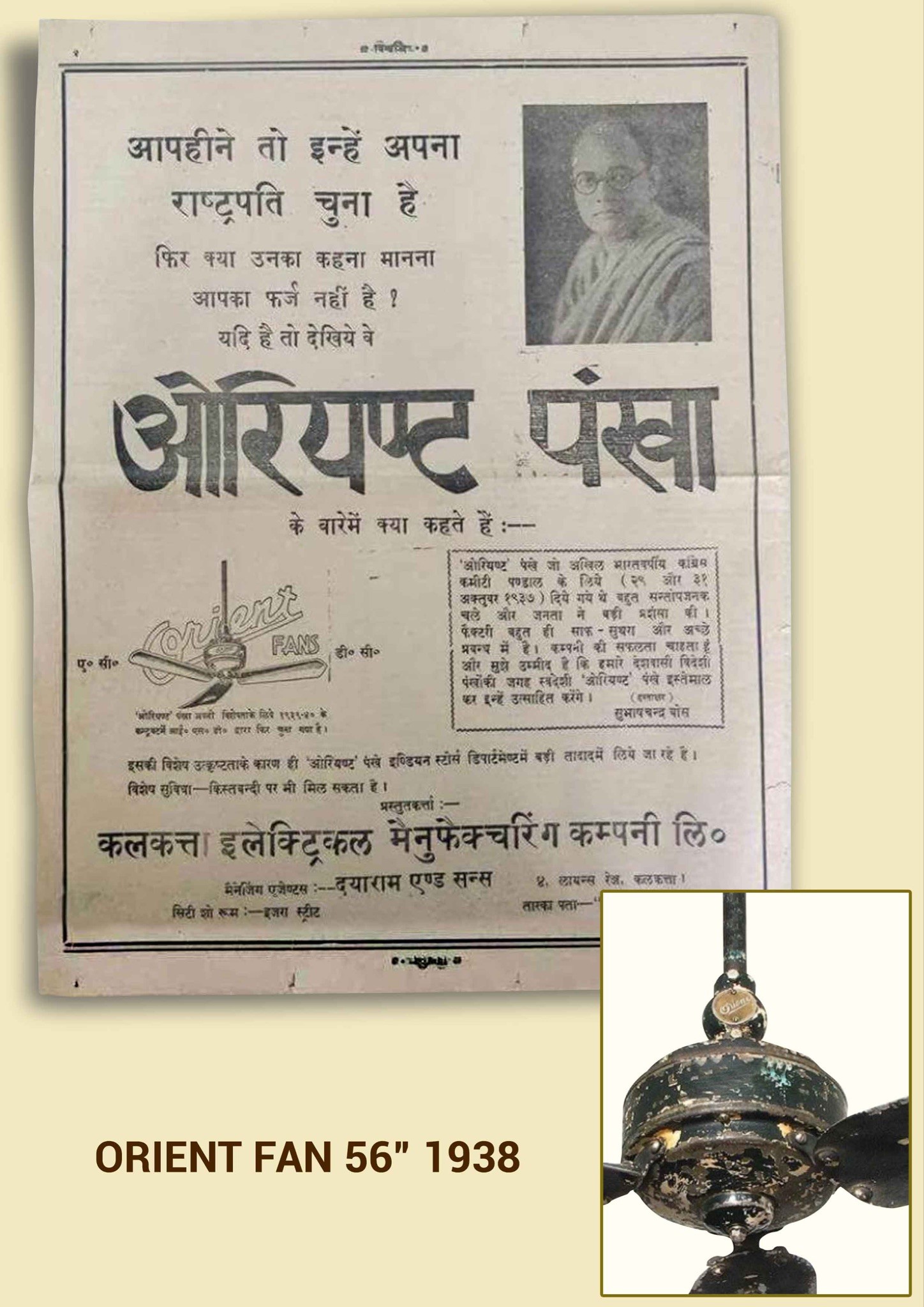

Orient Fans, which is currently a leading Fan Brand in India, is one of the very few pioneers of Indian fan manufacturing that not only survived over the years, but is thriving to date. The company dates back to the 1930s and it is evident through the newspaper ad that has a picture of Netaji Subhash Bose endorsing these fans that were used in the AICC pandal in Calcutta in October 1937. Interesting, Isn’t it?

The company manufacturing Orient Fans was later sold off to Birla’s in 1940’s and is still one of C K Birla’s flagship company.

Then there were Kassel Fans that are said to have been manufactured by Indian medium-sized manufacturers. Later it merged with Bajaj Electricals and even today some models remain in Kassels Brand in Bajaj fans portfolio.

Some other prominent names that contributed to the introduction of electric fans in India are Usha fans. The company was started by Sir Shriram a leading North Indian industrialist of those times. Initially started as a sewing machine company, they later started producing electric fans in 1946. This is also one of the early brands going strong till today.

The other major player was Crompton Parkinson, a subsidiary of the British company Crompton Parkinson which was taken over in 1947, by Mr. Karam Chand Thapar, founder of the Thapar Group and up to recently was in their fold as Crompton Greaves. Now it has changed hands but Crompton fans even today enjoy the premium-ness of yesteryears.

Another brand manufactured in Calcutta was POWER which was exceptionally well known for its DC ceiling fans (remember some generation and distribution of power supply was still DC till 1950’s). Later in the early seventies, the company along with their other brand Polar was sold off and is still on the market.

Sure, some of the old established names like GEC fans along with IEW, Clyde have been swept away with the passage of time but each one of them had an important role in the industrial revolution of Fans.

Concluding Remarks

While the details are still available and we could gather some historical details of the Calcutta origin of fans but up north in Amritsar too, a revolution happened in the fan industry. Most of the 100 odd manufacturers were small and tiny scale workshops born out of the partition of India and Pakistan. The numbers kept going down after 1950’s as they focussed only on North India and without any Brand building initiatives.

Few like Laxmi in Ludhiana (who also made Sewing Machines.) and Hero Fans in Amritsar (no relation to Hero Cycles) continued for some time.

In fact, the hugely popular Farrata fan (pedestal fan for rugged use) is a gift of the Punjab industry to the nation.

Recent Post

Categories

Tags

Bladeless Ceiling Fans BLDC Fans BLDC Motor Ceiling Fans Ceiling Fan Ceiling Fans Dual Blades in Portable Fans Energy Saving Fans Fan Blades Fan Inverters Fan Regulator Fans Fans are Covid-19 warriors Guide to Buying Ceiling Fan History of Electric Fans History Of Fan IFMA IFMA Editorial Indian Fan Industry Induction Motors Ceiling Fan LED Ceiling Fans Low Noise Ceiling Fans Pankahs Pankha Museum Pedestal Fans Portable Fans Remote Control Fan Remote Control of Fans Star Rated Ceiling Fans Unique Blade