Importance of Engineering Simulations in Fan industry

For tomorrow’s products to become a reality,” Engineering Simulations” must become a part of the toolbox for every engineer, every product and throughout the entire life cycle. Simulations have helped to reduce time and costs of product development. In the past, simulation was a very limited resource that was only used in the design of complex industrial products. Now, it has become an integral part of the design process of almost every product. Product simulations are of course used to examine individual attributes — i.e. physical properties, performance, efficiency, stresses, acoustics etc. The most exciting fact however is that simulations are not only used for design validation, but also over the entire product cycle — from the early idea through manufacturing, operations and maintenance.

Take the example of a Ceiling fan and its design parameters. Plus going in depth into how these designs are resulting in the performance being shown through this methodology.

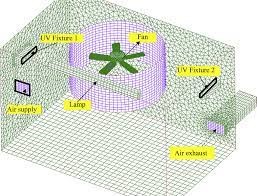

As per the IS standard, Virtual rooms are created inside Design modeller of simulation software. Ceiling fan is hung from ceiling and rotation is given to the fan. Computational Fluid Dynamics (CFD) analysis procedure followed up as, Particularly, CFD Analysis is performed on the designed ceiling fan to analyse the airflow around the area of interest. Mixing of air from top to bottom of the area so as to neutralize the change in temperature.

The study is interesting, quick and results accurate to reach the following..

- Formulate the Flow Problem.

- Model the Geometry and Flow Domain.

- Establish the Boundary and Initial Conditions.

- Generate the Grid. ( Image 01)

- Establish the Simulation Strategy.

- Establish the Input Parameters and Files.

- Perform the Simulation.

- Monitor the Simulation for Completion.

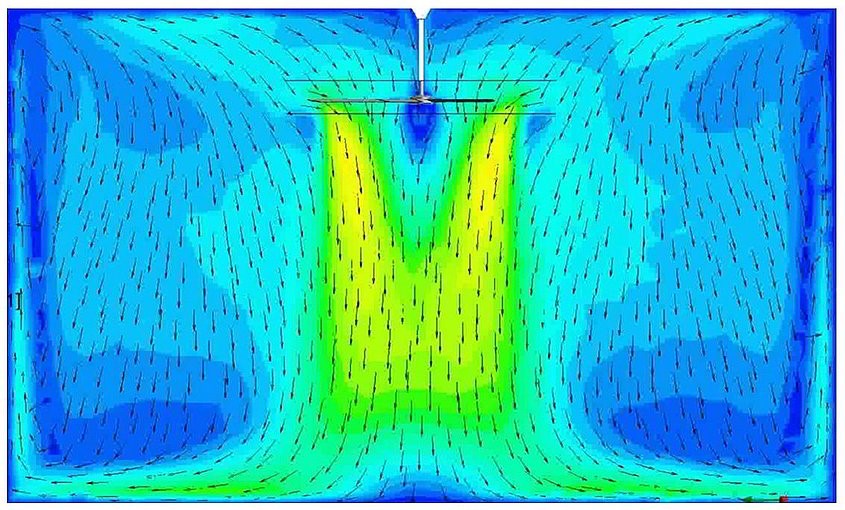

The air movement below the fan is captured by simulation software Computational Fluid dynamics (CFD). CFD clearly specify air movement beneath the fan & inside the room, air spread, air velocity, air rotation inside the room, air reach to the floor of room etc. CFD analysis helps to understand performance of Fan / Fan blades for change in parameters such as various angles, Width, shape, Cross section, thickness of blade etc.

This technology breakthrough throws up the advantage of using CFD study and analysis to save time and money on different physical iterations. And have better performing product.